At Bourquin, printing packaging is not just about printing performance. We support our customers holistically with all aspects of packaging printing. This includes a high-performance pre-press stage with expert data preparation and professional adaptation to the selected printing process.

Whether feasibility analysis, design creation, process-technical support or individual high-quality packaging printing – we have the necessary technological knowledge and are manufacturers of a diverse range of printing processes. Our colour management with proof technology, matched to the corresponding printing presses, enables the best control of packaging printing in advance and ensures consistent quality in the implementation of the defined printing process.

Flexo printing

Flexo printing is a very simple and universally applicable printing process, which is mainly used in the field of packaging printing. It is a direct letterpress process in which ink-bearing and non-ink-bearing surfaces are positioned at different heights on the flexible printing forme. A wide variety of materials can be printed for primary and secondary packaging, from small to very large runs.

Paper is printed with food-safe water-based inks. Very good printing results are achieved when printing on paper and corrugated cardboard. Flexo printing is particularly suitable for solids and halftones. In the reproduction of images, the highest print quality is achieved through the use of the latest technologies in the pre-press, printing plate production and machine technology. In flexographic printing, very different machine technologies have developed in recent years and a general distinction is made between preprint and postprint. Flexo printing is traditionally used for transport packaging, shelf-ready packaging/trays and shipping packaging.

-> Preprint (corrugated cardboard preprint) – here the outer paper surface of the corrugated cardboard is printed first and then laminated onto the corrugated cardboard with the inner web = roll preprint.

-> Postprint (corrugated cardboard direct printing) – this is a form of flexo printing where the paper is printed directly onto the corrugated cardboard.

Offset printing

Offset printing is a flat printing process. Here, the ink-receiving areas are etched out of a flat metal printing plate. The amount of ink transferred is measured in lines/cm for all printing processes. In offset printing (up to 100 lines/cm), more lines/cm can be printed on the substrate than in flexo printing (18 to 54 lines/cm). The higher the number of lines, the clearer the printed image when viewed up close. As an indirect flat printing process, it is based on the physical principle of grease-water repulsion. The printing and non-printing areas are almost on the same level. Offset printing uses highly viscous inks.

These inks are transferred to the paper by the so-called printing forme cylinder (unreversed) and the blanket cylinder (reversed). Offset printing inks are paste-like inks that dry through oxidation. In printing, we speak of standard colours (CMYK) and special colours. The special colours can be printed in offset from the different colour systems such as Pantone, RAL or HKS (for example brand logos) precisely and true to colour. The standard colours are screened in offset printing. Since the pixels are printed next to and on top of each other, a very fine screening is created. This creates a mixed colour for the viewer, so that a wide colour spectrum is possible. We create visual and haptic experiences by refining offset printing.

We often use varnishes for high-gloss and matt effects or Iriodin varnish for pearlescent effects. Blind and foil embossing gently emphasise graphic or text elements in offset printing. Offset print finishes can also be applied for quality reasons. An aqueous coating, for example, supports faster drying and helps to increase rub resistance. Offset printing can be enhanced with anti-slip varnish. Lamination (cellophaning) also protects the offset print image from mechanical impact.

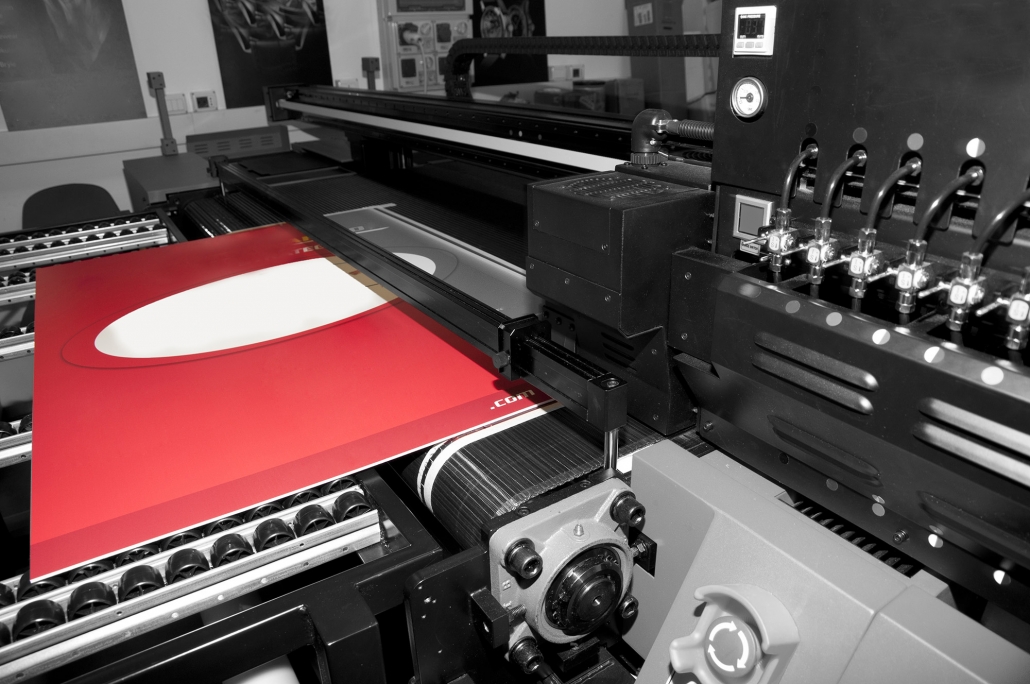

Digital printing

This printing process is a non-contact printing process. This means that no separate print carrier/print forme is required. The print image is transferred directly to the printing machine by computer.

Compared to other processes, such as offset or flexo printing, this eliminates the need for complex machine set-up. Digital printing is suitable for short runs and medium run lengths of various formats. Due to the low setup costs, there are good cost advantages compared to other printing processes. In terms of resolution, digital printing is comparable to offset printing. Therefore, digital printing is optimal for high-quality packaging and displays in smaller print runs.